At first, it may look like an impossible challenge. How do you create a high-quality product in a short space of time for the least amount of money? Two of the three, sure – but finding a balance between the trinity is no easy task. Though it may not appear so at first glance, the solution is rapid prototyping.

For those who aren't familiar with the term, rapid prototyping is the creation of a scale model using techniques such as 3D printing, casting, and CNC. As the last two fall nicely into the ACTech wheelhouse, it's those we'll focus on in this blog.

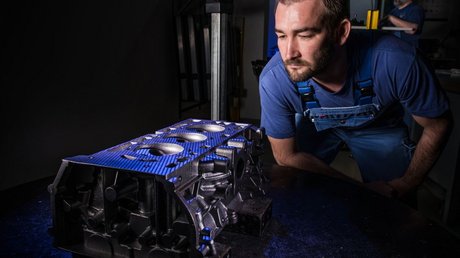

Prototyping begins with a CAD file and ends with a fully functional part. Having a working piece allows for testing, refinement, and follow-up iterations that ultimately result in a better final product. As the process involves creating a mold, parts can even be produced in small batches or replicated whenever necessary.